VIBRATION CONTROL

Sophisticated manufacturing machines and the need to achieve high productivity levels, without compromising good environmental conditions, requires developing new technologies to isolate and control vibration.

In the past, anchoring equipment to heavy concrete foundations was a common practice due to the lack of suitable materials to isolate vibrations.

Vibration is generally originated in the operation of unbalanced rotary equipment and reciprocating or impact machines. When this equipment remains anchored additional efforts increase wear and transmit disturbance, causing noise and vibration more or less perceptible but always harmful.

Noise and vibration are disturbing factors that:

Tire the worker lowering productivity. Permanently wear out equipment. Damage structures.

Vibration= Higher operation costs Diminished productivity due to workers fatigue Lower life cycle of equipment and facilities

L Series Vibration Levelers

It is now possible to control unwanted vibration and compensate for floor irregularities, with one device.*

The elastomer element of the vibration leveler is resistant to oil and chemical agents. Its lifecycle is practically wear free, its metal component is treated to assure a long life cycle.

No fillers (flecha) Unaffected by weather, chemicals, grease and oil

No anchoring (flecha) Lower installation cost.

Unaffected by weather, chemicals, grease and oil. (flecha). Zero maintenance cost.

Uses

Lathes

Mills.

Grinding machines

Presses

Stampers

Plastic and rubber injection machines

Do you wish to relocate your equipment?…just lift it and move it .. that’s it!

L series vibrating levelers, reengineering’s great helper.

| MODEL |

MEASUREMENTS IN MM |

MAXIMUM LOAD

Lbs

|

| D |

A |

D SCREW |

| DL-70 |

70 |

24 |

11 |

555.5 |

| L-120 |

110 |

31 |

16 |

2888.8 |

| L-160 |

160 |

40 |

19 |

7777.7 |

| L-200 |

208 |

45 |

25.4 |

13333.3 |

* L series vibration levelers absorb height difference between the equipment’s supports. Still, it is important to note that the support surface on which the vibrating levelers rest should be completely horizontal.

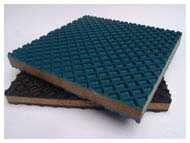

Neocork ® Elastomer Vibration Isolator

Neocork is a hybrid material that combines the vibration isolating properties of cork with the shock absorbing of a balanced mix of elastomers. The result is a material with exceptional vibration isolating properties, which can be used to solve a great number of vibration problems. Delivering high isolation levels (70% to 95%) in most uses, depending of the frequency of the vibrating energy and the load the support receives.

Neocork resists wear due to

Weather

Grease and oil

Chemical agents

Neocork,

The antivibrating plate that responds

More effective

More resistant

Less expensive

Cut it

Position it without adhesives or anchors

Remove it and install it again

| PRODUCT |

ID |

SIZE |

LOAD

CAPACITY |

| NEOCORKMR L |

BLACK |

24" x 36" x 1" |

3.5 Kg/cm2 |

| NEOCORKMR L |

BLACK |

24" x 18" x 1" |

3.5 Kg/cm2 |

| NEOCORKMR H |

BLUE |

24" x 36" x 1" |

7.5 Kg/cm2 |

| NEOCORKMR H |

BLUE |

24" x 18" x 1" |

7.5 Kg/cm2 |

* The attenuation theory is complex and highly specialized. If you need to know precisely the isolating percentage, you must contact our technical department, we will be glad to help you.

|

|